Grinding Glass -Grit

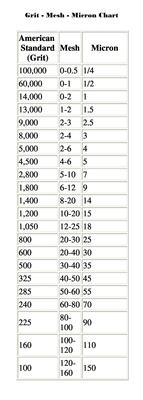

Grit is a kind of abrasive powder which when rubbed against a material grinds it down. It comes in various sizes and degrees of fineness, usually expressed in the form of mesh size. Mesh size means how many lines of sieve per inch it could pass through. For e.g.- a mesh size of 9 means there are 9 openings per linear inch in the sieve. The size of each opening is determined by the number of openings per inch and the thickness of the wires. If I made a grid it would pass through a sieve with holes of size 9 microns. Also every grit is associated with a number; a 200 grit means if I took a sieve with 200 holes in one inch the grit would pass through. They basically tell us about fineness of the grit.

For glass grinding we will first use large, less fine grits (80,120 etc.) to do rough grinding and get the required shape. After which we will use finer grits to polish the surface.

Usually grit is seen on sandpapers and grinders, however for our purpose we need powdered grit for flexibility in grinding.

We will be using Silicon carbide (SiC) grit because it is useful for wet sanding applications. When we grind glass, a lot of it is turned into glass dust. Thus we constantly need to keep adding water as glass dust is harmful if inhaled.

- 40 grit: Coarse

- 80 grit: Medium

- 100 grit: Medium

- 120 grit: Fine

- 220 grit: Fine

- 440 grit: Extra Fine